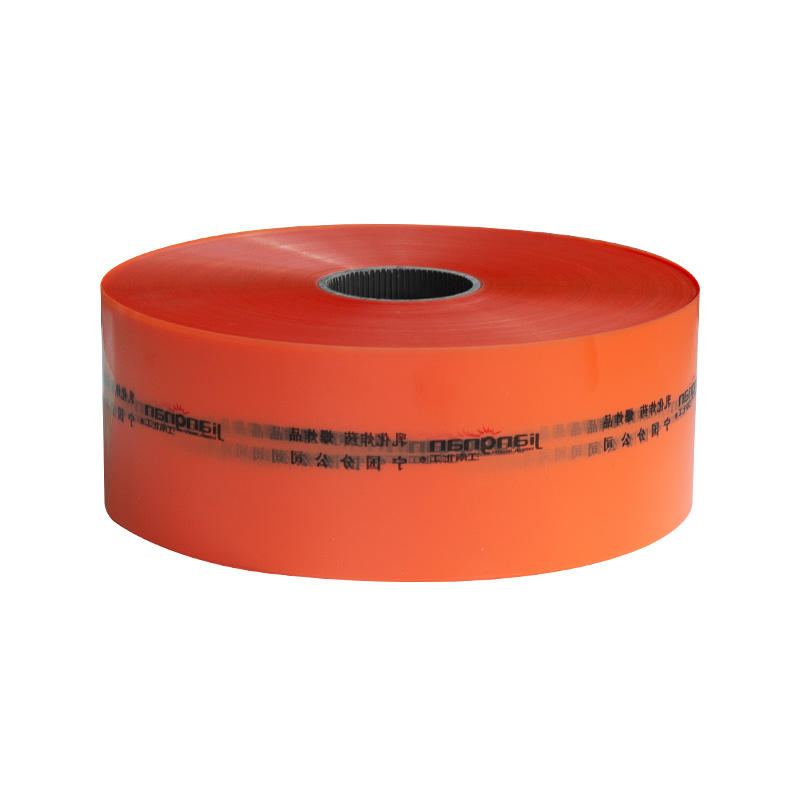

Zhejiang Changxing Zixin Technology Co., Ltd. Professional emulsion explosive composite plastic film manufacturer

-

0

Years of Industry Experience

-

0+

Enterprise Employee

-

0+

Cooperative Partner

Zhejiang Changxing Zixin Technology Co., Ltd. is located in Changxing County, Zhejiang Province (Coal Mountain Town Baixian Industrial Park). The local economy ranks among the top 100 in the country, making it an open and prosperous area. Located at the intersection of Zhejiang, Jiangsu and Anhui provinces, we are less than two kilometers away from the Hangchang Expressway Coal Mountain North exit toll station and have unique raw material resources, convenient transportation locations and rich resources of technical information, among other advantages.

In late 2012, in line with the direction of the industry and market demand, following extensive market research and careful planning, we decided to develop and produce emulsion explosive composite plastic films using advanced equipment, processes and technologies. Over the past seven years, we have introduced advanced production lines with more significant production advantages, including high-performance rotary head blown film units, dry composite units, printing units, slitting units and other three composite film production lines. There are more than 60 workers and a technical research and development team of more than 20 people. In addition, to comply with market requirements and national environmental protection requirements, the company last year introduced an advanced foreign production line with an annual capacity of 5,000 tons of composite film for various types of explosive automatic packing machines.

Industrial Product Packaging PE/PP Co-extruded Film Suppliers and Custom Industrial Product Packaging PE/PP Co-extruded Film Factory in China. After a long period of accumulation and a good reputation, we have won the favor of a large number of high-quality customer units, with a total annual sales of 3,000 tons.

Certificate Display

We attach great importance to quality and environmental protection, and have successfully obtained IATF16949 quality system certification and ISO14001 environmental management system certification. Custom Industrial product packaging film.

Latest News

-

How does multi-layer co-extrusion technology help improve the performance of PP co-extruded films?

2024-05-13 Industry News

Multi-layer co-extrusion technology helps improve the performance of P...READ MORE -

How to improve the uniformity of PP co-extruded film?

2024-05-09 Industry News

In modern industry and materials science, PP coextruded film has attra...READ MORE -

Why is highly flexible PE packaging film highly flexible?

2024-04-30 Industry News

The reason why highly flexible PE packaging film is highly flexible is...READ MORE -

Why can strong cross-film become the packaging of emulsion explosives?

2024-04-24 Industry News

Strong cross film can be used as a specialized packaging material for ...READ MORE -

Why does strong cross film need explosion-proof performance?

2024-04-17 Industry News

The main reasons why strong cross film requires explosion-proof perfor...READ MORE

English

English 中文简体

中文简体